Compressors Made Simple: What They Are and How They Work

What They Are and How They Work

Table of Contents

ToggleUnderstanding the Basics of Compressors

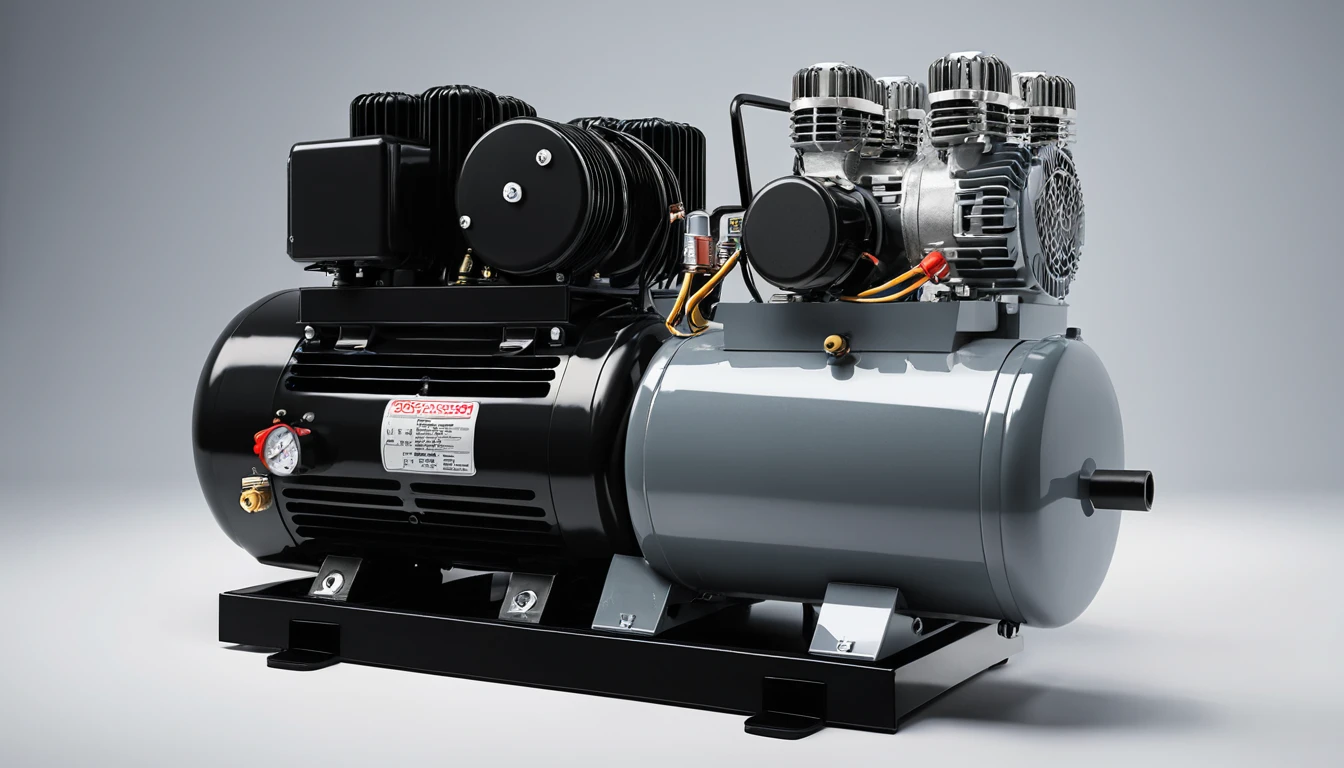

Compressors are essential devices that play a critical role in various industries, from construction and automotive to home appliances. At their core, compressor convert power into potential energy stored in pressurized air or gas. This stored energy is then used to perform various tasks, such as powering pneumatic tools, inflating tires, or operating refrigeration systems. Understanding how compressors work can demystify their applications and help you choose the right type for your needs.

Hyundai Power: A Trusted Name in Industrial Tools

When it comes to reliable industrial tools, Hyundai Power stands out as a trusted brand. Hyundai Power offers a wide range of Hyundai-branded products, including power generators, home appliances, solar solutions, lighting, gardening tools, and industrial equipment. Known for their durability and innovation, Hyundai Power products are designed to meet the diverse needs of both professionals and homeowners, making them an excellent choice for compressor-related applications.

How Do Compressors Work?

Compressors operate by increasing the pressure of a gas or air while reducing its volume. This process involves capturing air from the environment and compressing it in a chamber using a mechanical force, such as a piston or a rotating blade. Once compressed, the high-pressure air is stored in a tank, ready to be released to power tools or equipment.

The energy transformation follows three key stages:

- Intake Stage: Air is drawn into the compressor.

- Compression Stage: The air is pressurized by mechanical components.

- Discharge Stage: The compressed air is released for use.

This straightforward mechanism allows compressors to be versatile and efficient in various applications.

Different Types of Compressors

There are several types of compressors, each tailored to specific tasks and industries:

- Reciprocating Compressors: These use pistons and cylinders to compress air, making them ideal for smaller, high-pressure tasks like inflating tires.

- Rotary Screw Compressors: Common in industrial settings, these use rotating screws to compress air, providing a continuous supply.

- Centrifugal Compressors: Designed for large-scale operations, they use high-speed rotating impellers for compressing air.

- Scroll Compressors: Often found in HVAC systems, these are quieter and more energy-efficient.

Each type has unique advantages, making it important to choose one based on your specific requirements.

Key Applications of Compressors

Compressors are vital across numerous industries. Some of their common applications include:

- Construction: Powering pneumatic tools like jackhammers and nail guns.

- Automotive: Inflating tires and operating spray guns.

- Manufacturing: Facilitating assembly line operations.

- Home Use: Running tools for DIY projects or inflating sports equipment.

Their adaptability and efficiency make them indispensable in both professional and personal settings.

Benefits of Using Compressors

The widespread use of compressors is attributed to their numerous benefits:

- Energy Efficiency: Compressors can store energy for use when needed, reducing power wastage.

- Versatility: They work with a variety of tools and equipment.

- Cost-Effectiveness: Over time, compressors save costs by minimizing energy consumption and streamlining operations.

- Reliability: With proper maintenance, compressors offer consistent performance over long periods.

These advantages make compressors an excellent investment for industries and households alike.

Maintenance Tips for Long-Lasting Performance

To ensure your compressor performs optimally, regular maintenance is essential. Here are some tips:

- Check for Leaks: Inspect hoses and connections for air leaks that can reduce efficiency.

- Change Filters Regularly: Dirty filters can restrict airflow and strain the compressor.

- Monitor Oil Levels: For oil-lubricated compressors, maintaining the correct oil level is crucial.

- Keep It Clean: Dust and debris can clog the machine, so regular cleaning is a must.

- Store Properly: Keep your compressor in a cool, dry place to prevent rust and damage.

Following these steps can significantly enhance the lifespan of your compressor.

Choosing the Right Compressor for Your Needs

Selecting the right compressor depends on your intended use. For home projects, a small reciprocating compressor might suffice, while industrial tasks may require a rotary screw or centrifugal compressor. Consider factors like pressure requirements, portability, noise levels, and budget when making your decision.

Conclusion: Compressors Simplified

Compressors are versatile tools that make countless tasks easier and more efficient. Whether you’re a professional in the construction industry or a homeowner tackling DIY projects, understanding how compressors work and their various types can help you maximize their benefits. With trusted brands like Hyundai Power offering a range of industrial tools, finding a reliable compressor that meets your needs has never been easier.