The automotive industry is constantly evolving and so are the PCB design guidelines that govern it. As new technologies and materials are introduced, the guidelines are updated to ensure that the products produced are of the highest quality and meet the safety standards required by the automotive industry.

Automotive PCB Design Guidelines

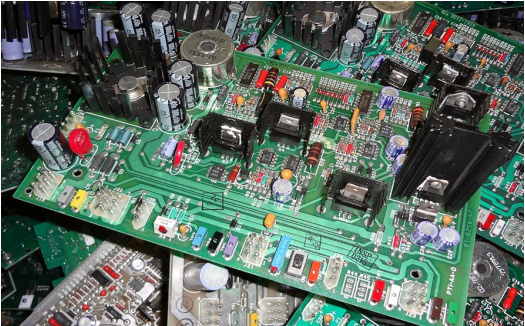

The automotive industry is one of the most demanding industries when it comes to the design and manufacture of printed circuit boards (PCBs). The PCBs used in automotive applications must meet extremely high standards for reliability, durability, and performance.

To meet these challenges, automotive PCB designers must adhere to a set of specific design guidelines. In this blog post, we will discuss the most important automotive PCB design guidelines.

- Use Only High-Quality Components

When designing automotive PCBs, only high-quality components should be used. This is because the components used in automotive applications must be able to withstand extreme temperatures, vibrations, and other harsh conditions.

- Use Automotive-Grade PCB Materials

Automotive-grade PCB materials are designed to meet the specific needs of the automotive industry. These materials are more resistant to thermal and mechanical stresses than standard PCB materials.

- Design for Thermal Management

Thermal management is critical in automotive PCB design. The components used in automotive applications generate a lot of heat, and the PCB must be designed to dissipate this heat.

- Use High-Speed Connectors

Automotive PCBs must be designed for high-speed data transfer. This means that high-speed connectors must be used in order to minimize signal loss.

- Follow Rigid PCB Design Guidelines

Rigid PCBs are the preferred choice for automotive applications. This is because they are more resistant to thermal and mechanical stresses than flex PCBs.

- Use Multiple Layers

Multilayer PCBs are typically used in automotive applications. This is because they offer better thermal management and improved signal integrity.

- Follow Stringent Quality Control Procedures

Automotive PCBs must meet extremely high standards for quality and reliability. To ensure that these standards are met, strict quality control procedures must be followed during the design and manufacturing process.

The Importance of Automotive PCB Design Guidelines

As the automotive industry looks to electrification to meet stricter emissions regulations, the demand for more sophisticated and reliable electronic control systems is increasing. Printed circuit boards (PCBs) are a critical component of these control systems, and the design and manufacture of automotive PCBs is subject to a number of specific guidelines.

In order to ensure the safety and reliability of automotive PCBs, designers must adhere to a number of design guidelines. These guidelines cover a range of topics, from material selection to thermal management.

One of the most important aspects of automotive PCB design is the selection of materials. The majority of automotive PCBs are made from FR-4, a fire-retardant material that is resistant to high temperatures. However, there are a number of othermaterials that can be used for automotive PCBs, depending on the application.

Another important consideration in automotive PCB design is thermal management. Automotive electronics are subject to a wide range of temperatures, from the cold of a winter morning to the heat of a summer day. As such, it is important to ensure that the PCB is designed to dissipate heat effectively.

There are a number of other factors that must be considered when designing automotive PCBs, including electromagnetic compatibility (EMC), mechanical stress, and vibration resistance. By following the relevant guidelines, designers can ensure that their automotive PCBs are safe, reliable, and fit for purpose.

3. The Benefits of Automotive PCB Design Guidelines

As the automotive industry moves towards ever more electrification, the importance of designing reliable and safe PCBs (printed circuit boards) increases. To meet this challenge, the automotive industry has developed a set of guidelines for designing and manufacturing PCBs.

The benefits of following these guidelines include:

- Increased reliability

Automotive PCBs are subject to a wide range of environmental conditions, from extreme temperatures to vibration and shock. By following the design guidelines, manufacturers can ensure that their PCBs are able to withstand these conditions and continue to function correctly.

- Improved safety

As well as being reliable, automotive PCBs must also be safe. In particular, they must not release harmful chemicals or fumes in the event of a fire. By following the design guidelines, manufacturers can ensure that their PCBs meet these safety requirements.

- Reduced costs

By following the design guidelines, manufacturers can avoid making costly mistakes that could result in delays or recalls. In addition, the guidelines can help to ensure that PCBs are designed and manufactured efficiently, resulting in lower costs.

The Different Types of Automotive PCB Design Guidelines

When it comes to designing printed circuit boards (PCBs) for the automotive industry, there are a few key guidelines that must be followed in order to ensure the end product is up to snuff. In this blog post, we’ll take a closer look at four of the most important types of automotive PCB design guidelines:

- Thermal Management

One of the most important aspects of automotive PCB design is thermal management. Due to the fact that automotive electronics are often placed in close proximity to heat-generating components, it’s important to ensure that the PCB is designed in such a way that it can dissipate heat effectively. This can be accomplished through the use of thermal vias, copper planes, and other similar techniques.

- Signal Integrity

Another important consideration for automotive PCB design is signal integrity. Due to the fact that automotive electronics are often required to operate at high speeds, it’s important to ensure that the PCB is designed in such a way that it can support high-speed signals without any Issues. This can be accomplished through the use of impedance-controlled trace routing, differential pair routing, and other similar techniques.

- EMC/EMI

Another important consideration for automotive PCB design is electromagnetic compatibility (EMC). Due to the fact that automotive electronics are often required to operate in close proximity to high-powered electromagnetic sources (such as the engine), it’s important to ensure that the PCB is designed in such a way that it won’t be adversely affected by these sources. This can be accomplished through the use of shielding, filtering, and other similar techniques.

- Cost

Finally, it’s important to consider the cost of the automotive PCB when designing it. Due to the fact that automotive electronics are often required to be mass-produced, it’s important to ensure that the PCB is designed in such a way that it can be manufactured cheaply. This can be accomplished through the use of simple trace routing, via stitching, and other similar techniques.

Following automotive PCB design guidelines can also help to reduce the costs of the system. By designing a system that is easier to manufacture and test, designers can help to reduce the overall costs of the system.