In the pursuit of material excellence for high-stress environments, Custom 455 stainless steel has emerged as a superior choice due to its remarkable properties. This specialized alloy is designed to meet the rigorous demands of applications where strength, durability, and performance are critical. This article explores the benefits of Custom 455 stainless steel, its applications in various industries, and why it is a preferred material for high-stress environments.

Understanding Custom 455 Stainless Steel

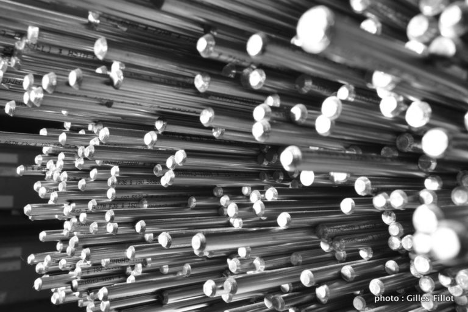

Custom 455 stainless steel is a high-performance martensitic stainless steel known for its exceptional strength and toughness. The alloy is engineered to provide superior mechanical properties compared to standard stainless steels, making it an ideal material for demanding applications.

The key to its enhanced performance lies in its composition, which includes chromium, nickel, and a small amount of copper. This combination not only imparts excellent corrosion resistance but also ensures high strength and hardness. The alloy undergoes a heat treatment process that optimizes its mechanical properties, making it suitable for applications where traditional stainless steels might fall short.

Superior Mechanical Properties

One of the standout features of Custom 455 stainless steel is its superior mechanical properties. It offers high tensile strength, making it suitable for components that must withstand substantial stress and load. Its yield strength is significantly higher than that of standard stainless steels, allowing it to maintain structural integrity under extreme conditions.

Moreover, Custom 455 stainless steel exhibits excellent fatigue resistance, which is crucial for components subjected to cyclic loading. This property helps in reducing the likelihood of failure due to repeated stress, thereby extending the lifespan of the components made from this alloy.

Corrosion and Wear Resistance

In addition to its strength, Custom 455 stainless steel provides excellent corrosion resistance, making it suitable for use in harsh environments where exposure to moisture, chemicals, or high temperatures is a concern. The alloy’s chromium content enhances its resistance to oxidation and corrosion, ensuring that it remains functional even in challenging conditions.

Wear resistance is another critical factor where Custom 455 stainless steel excels. The alloy’s hardness and strength contribute to its ability to withstand abrasive forces, reducing wear and tear on components. This characteristic is particularly valuable in applications where components are subject to constant friction or contact with other surfaces.

Applications in High-Stress Environments

Custom 455 stainless steel is widely used in various industries where high performance and durability are essential. Some notable applications include:

- Aerospace Industry: In aerospace engineering, Custom 455 stainless steel is used for manufacturing critical components such as turbine blades, landing gear components, and structural parts. The alloy’s high strength-to-weight ratio and resistance to high temperatures make it ideal for these demanding applications.

- Automotive Industry: The automotive sector utilizes Custom 455 stainless steel in parts that require high strength and durability, such as engine components, transmission parts, and suspension systems. The alloy’s fatigue resistance and wear resistance are crucial for maintaining performance and reliability in vehicles.

- Oil and Gas Industry: Components used in the oil and gas industry, including valves, pumps, and connectors, benefit from the corrosion and wear resistance of Custom 455 stainless steel. The alloy’s ability to withstand harsh environmental conditions ensures the longevity and reliability of these critical components.

- Medical Devices: Custom 455 stainless steel is also employed in the medical field for surgical instruments and implants. The alloy’s biocompatibility, combined with its strength and resistance to corrosion, makes it suitable for use in medical applications where precision and durability are paramount.

Manufacturing and Fabrication

The fabrication of components using Custom 455 stainless steel requires specialized techniques to fully utilize the alloy’s properties. Heat treatment plays a significant role in achieving the desired strength and hardness. Precision machining and fabrication processes are employed to ensure that components meet the stringent specifications required for high-stress environments.

Custom 455 stainless steel can be welded, although it requires careful control of heat input and cooling rates to prevent changes in its mechanical properties. The alloy’s high strength can also pose challenges during machining, necessitating the use of advanced tools and techniques to achieve the desired finish and dimensions.

Conclusion

Custom 455 stainless steel stands out as a material of choice for high-stress environments due to its exceptional mechanical properties, corrosion resistance, and wear resistance. Its ability to perform reliably under demanding conditions makes it indispensable in industries such as aerospace, automotive, oil and gas, and medical devices. The alloy’s advanced composition and processing requirements ensure that it delivers outstanding durability and performance, providing a robust solution for applications where conventional materials might fall short. As industries continue to push the boundaries of technology and performance, Custom 455 stainless steel will remain a critical component in achieving these goals.