In the vibrant world of aluminum production, Aluminium Wire Rod Rolling Mills stand as technological marvels, crafting raw aluminum into precisely shaped wire rods. This article unravels the intricacies of Aluminium Wire Rod Rolling Mills, exploring their significance, core processes, applications, and the technological advancements that propel them to the forefront of the aluminum manufacturing landscape aluminium wire rod rolling mill.

Decoding the Significance of Aluminium Wire Rod Rolling Mills

Aluminium Wire Rod Rolling Mills play a pivotal role in transforming aluminum billets or ingots into wire rods with specific diameters and properties. These mills are the final touchpoint in the production journey, where hot-rolled aluminum wire rods are crafted to meet stringent industry standards. The versatility of these wire rods makes them indispensable in applications ranging from electrical wiring to general manufacturing.

Core Processes in Aluminium Wire Rod Rolling Mills

1. Heating and Rolling:

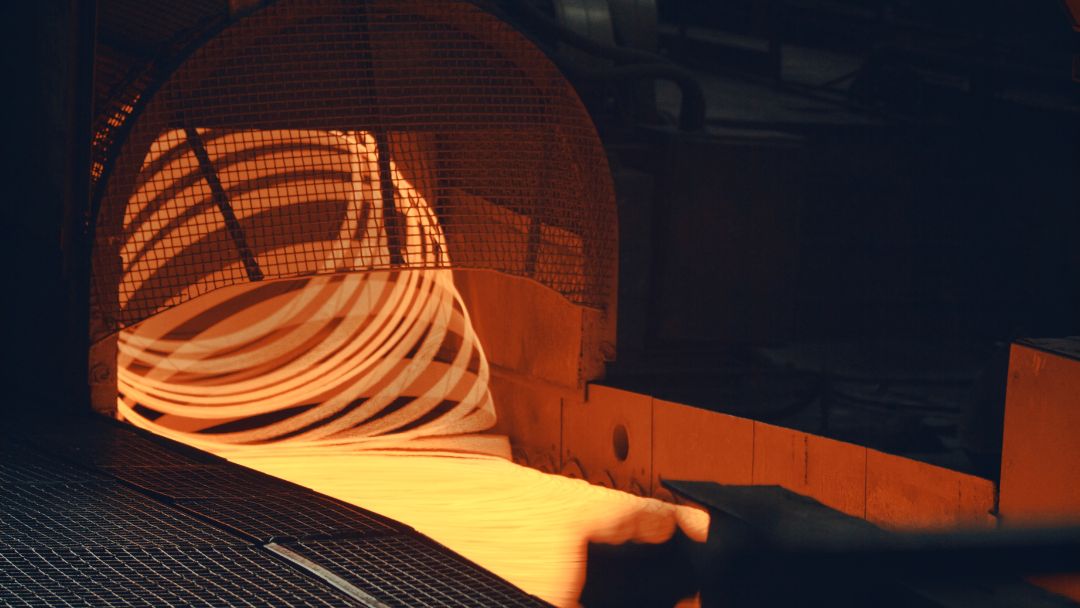

- Aluminum billets or ingots are heated to a specific temperature in a furnace.

- The heated aluminum is then passed through a series of rolling stands to reduce its diameter to the desired size.

2. Cooling and Coiling:

- The hot-rolled wire rods are rapidly cooled to set their structure and properties.

- The cooled wire rods are then coiled for ease of handling and transportation.

3. Surface Treatment:

- Depending on the intended application, the wire rods may undergo surface treatments, such as pickling or coating, to enhance their properties.

4. Quality Inspection:

- In-line quality inspection systems are employed to ensure that the wire rods meet specified dimensional and metallurgical requirements.

Applications Across Industries

The wire rods produced by Aluminium Wire Rod Rolling Mills find applications across diverse industries, including:

- Electrical Industry: Utilized in the production of conductors for electrical cables and wiring.

- Construction Sector: Used for manufacturing construction materials, fasteners, and structural components.

- Automotive Manufacturing: Employed in the production of various automotive components, from fasteners to decorative elements.

- General Manufacturing: Used in a myriad of industries for crafting a wide range of products.

Technological Advancements in Aluminium Wire Rod Rolling Mills

Advancements in Aluminium Wire Rod Rolling Mill technology contribute to enhanced efficiency and product quality:

- Advanced Rolling Mill Designs: Incorporation of advanced roll designs for improved precision and dimensional control.

- Automation and Control Systems: Integration of automated control systems for real-time monitoring and adjustment of the rolling process.

- In-line Quality Inspection: Use of advanced in-line inspection systems for comprehensive quality control.

Considerations in Aluminium Wire Rod Rolling Mill Operation

Efficient operation of Aluminium Wire Rod Rolling Mills involves careful considerations:

- Raw Material Quality: Ensuring the quality and composition of the input aluminum billets or ingots.

- Roll Maintenance: Regular maintenance of rolls to ensure their proper functionality and longevity.

- Quality Control Measures: Implementing stringent quality control measures to guarantee the production of high-quality wire rods with consistent properties.

Conclusion

Aluminium Wire Rod Rolling Mills stand as pioneers of precision in the aluminum industry, transforming raw aluminum into versatile wire rods that drive innovation across sectors. Their significance in providing essential materials for various industries, coupled with continual technological advancements, positions them at the forefront of the aluminum manufacturing landscape. As industries evolve and demand increases, Aluminium Wire Rod Rolling Mills continue to shape the future, one precisely rolled wire rod at a time.

Frequently Asked Questions (FAQs)

- What is the significance of Aluminium Wire Rod Rolling Mills in aluminum production?

- Aluminium Wire Rod Rolling Mills play a pivotal role in transforming aluminum billets or ingots into precisely shaped wire rods for various industries.

- What are the core processes in Aluminium Wire Rod Rolling Mills?

- Core processes include heating and rolling, cooling and coiling, surface treatment, and quality inspection to produce aluminum wire rods.

- Where are Aluminium wire rods used?

- Aluminium wire rods find applications in the electrical industry, construction sector, automotive manufacturing, and general manufacturing.

- What technological advancements have been made in Aluminium Wire Rod Rolling Mills?

- Advancements include advanced rolling mill designs, automation and control systems, and in-line quality inspection for improved efficiency and product quality.

- What considerations are important in Aluminium Wire Rod Rolling Mill operation?

- Ensuring raw material quality, regular roll maintenance, and implementing stringent quality control measures are crucial for efficient Aluminium Wire Rod Rolling Mill operation.